DHL Welcomes Baxter And Sawyers Robots As Warehouse Assitants

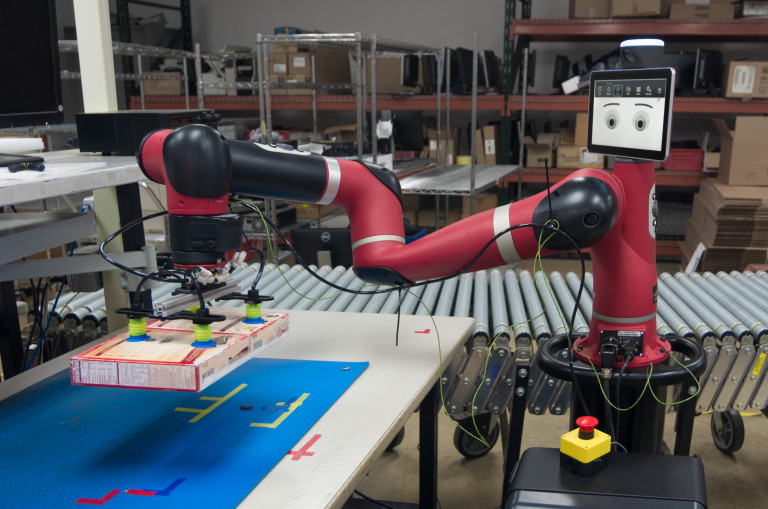

The advancement in any given industry is a must with transformation into the next-generation cutting edge technology. With that said, the courier giant DHL is currently trailing Baxter and Sawyer– a duo of smart and collaborative robots, inside its warehouse. Their assigned job being value-added tasks like knitting, assembly, packaging, pre-retail services.

An intelligent creation of Rethink technology–Baxter and Swayer proffer adaptable solutions that support warehouse staff and lend a hand to enhance productivity at DHL facilities. DHL is presently testing the ways to incorporate several Baxter and Sawyer robots into its different operational locations across the globe.

Innovative enough, DHL also purchased its maiden Sawyer robot and its research involve 3D printing opportunities to generate specific grippers for the robots to allow for supplementary duties to be fulfilled in the warehouse.

In a DHL press release on the 21, July 2016, Adrian Kumar, Vice President, Solutions Design, DHL Supply Chain North America, said ” Baxter and Sawyer robots are some of the most advanced collaborative robots in the market, and we plan to use them in a variety of packaging and inventory tasks that will allow us to deploy our employees for higher value work,” he continued, “By having these robots work in tandem with humans, we can ensure that our production lines are adjusting to changes and running more efficiently year-round.”

Markus Kückelhaus, Vice President Innovation and Trend Research, DHL Customer Solutions and Innovation, commented “The logistics industry has been unable to leverage smart, collaborative robots until recently, and the high-performance Sawyer robot is changing the game in what we can and cannot automate. We are excited about bringing flexibility and efficiency to our factory floor – enabling shorter cycle times, more uptime and helping our bottom line.”

DHL, in the beginning of this month, publicized that it has been operating a pilot trial using two EffiBOT automated trolleys from the Effidence — a French start-up for “collaborative automated order picking” installing it at of its warehouse in Unna, Germany.

With this attitude, DHL is heading its way towards another dimension of high-tech era.